VISION :

OUR VISION IS TO BE A MOST PREFARABLE KNIT TEXTILE AND DIGITAL SUBLIMATION MANUFACTURER FOR GLOBAL CLOTHING COMPANIES WITH HIGH VISIBILITY AND STRONG SUSTAINABILITY

MISSION:

OUR MISSION IS TO TAKE SRONG POSITION IN THE GARMETNS INDUSTRY BY OFFERING TREND –SETTING KNIT GARMETS AND DIGITAL SUBLIMATION IN THE GLOBAL MARKETS. WE WANT TO ENSURE INNOVATIVE,COST EFFECTIVE AND COMPETITIVE AND ENSURING ON TIME DELIVERY WITH QUALITY GOODS. WE WANT TO IMPROVE OUR PEOPLES LIFE BY PERTICIPATING SOCIAL ACTIVITES .

SEWING SECTION

SEWING SECTION

MUNZAREEN APPARELS With total 20 lines, our operators sew some 2,0000 garments each day.

Sewing : Sewing requires passions, creativity, attention, soul’s satisfaction and advanced technology. In fact, a highly trained operator with great thirsts expresses herself through her sewing craftsmanship & artistry. We just try to inspire taking her artistic mind here at ATG. Good finishing comes out from a choosy mind and good operational arrangement- we never compromise on quality.

CUTTING: Our cutting section controlled by experienced technical persons with their caring hands, we ensures optimum functioning of Cutting Section with exact quality. It adapts easily to different production requirements, from large orders to small, ultimately making significant savings in terms of production time and material consumption. Our cutting capacity is 10,000 pieces of garments per day.

Finishing:finishing work starts from the very beginning- good patterns, exact markers, precise cutting, bundling and careful sewing reduce undesired finishing touches.

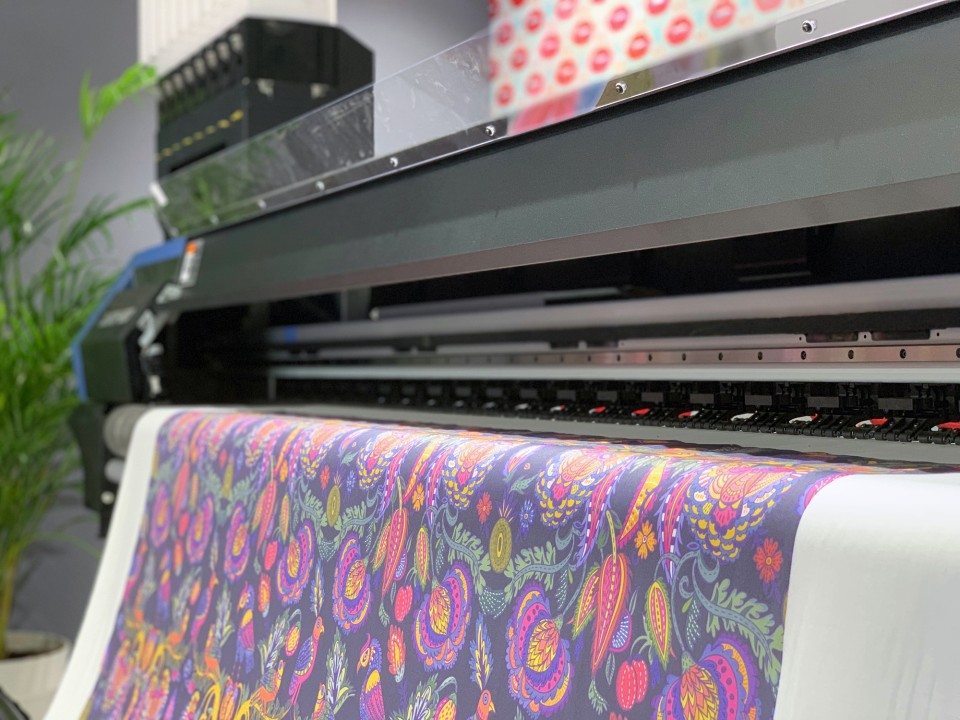

MUNZAREEN DIGITAL SUBLIMATION & PRINTING

We are proving high quality sublimation transfers, supplies,and more. We have latest head Epson that provide high quality print.

Why will you choose us for sublimation printing?

We guarantee high-quality, one-of-a-kind printed things that are practical, natural, and printed with low-effect inks. All of this is carried out on production lines that are powered by renewable energy. Along similar lines, we’re ready to help you choose the ideal print approach for your bespoke request, depending on what you require from it.

Rollar heatpress:

our rollar heatpress machine capacity to print transfer to 3000 meter each day.

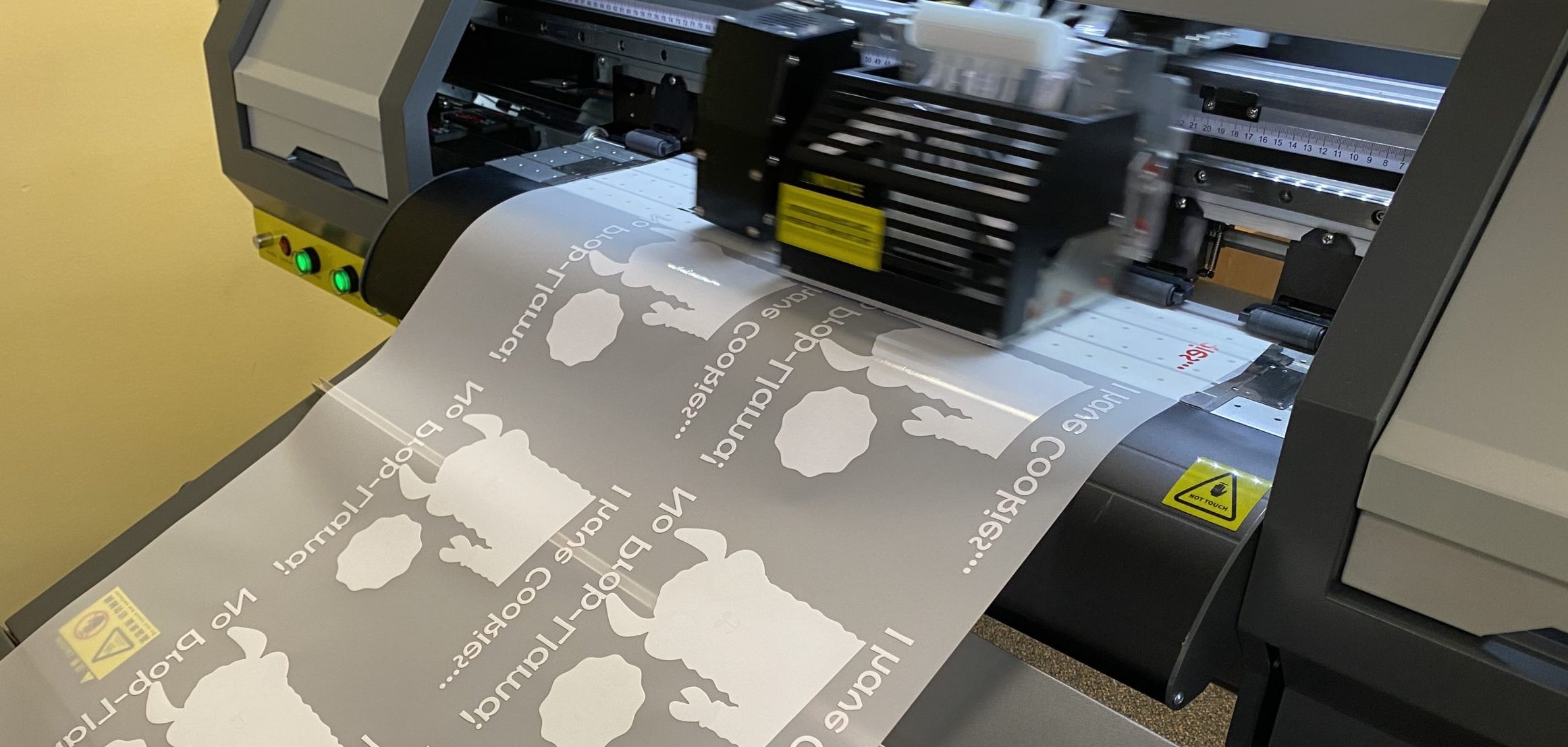

DTF (Direct-To-Film) printing:

DTF printing, often referred to as direct-to-film printing, is a process that comprises printing your design directly on a film before transferring it to various fabric types, including cotton, polyester, synthetic, or silk, regardless of their color. This method facilitates the use of white ink, so it can successfully accommodate designs that require it. DTF printing can produce full-size prints of the highest caliber, featuring vibrant hues and an unusually soft texture. DTF (Direct-To-Film) printing process is a type of transfer printing.our DTF production capacity is over 1500 meter each day.

UV-DTF (Direct-To-Film) printing:

UV DTF – Ultraviolet Direct To Film is a specialised printing process.Ready for application, no cutting or weeding. Transfer Tape included on top of print.** See application instructions below. **

High quality print, waterproof and scratch proof.

Use as a full wrap or cut to individual stickers.

Approx size of print 24.3cm x 10.7cm

SCREEN PRINT:

Cotton and cotton blends are popular choices for most textile screen printers. Cotton yarn is typically multifilament and as such, tends to absorb ink more readily than synthetics. Cotton knits in particular are often soft, whilst woven cotton can be cool in summer and warm in winter.

OUR SERVICE

OUR SERVICES

We work for readymade garments since 2014.Basically we manufacture T-shirts ,Polo, sports jersey,soprtswere,cap, jacket,Hoodies etc.

MUNZAREEN APPARELS have 20 lines, our operators sew some 20000 garments each day.

MUNZAREEN DIGITAL SUBLIMATION & PRINTING provide quality work for your satisfaction, we have tremendous team to work together and provide quality transfers, supplies and more.

Merchandising:

liaison with factories on all production issues. communicate to customer with the production status and follow customer instructions.

compliance

Giving priority compliance level at all production unit.

Quality

Our products units section terms are depend on products range, quality of control process, Products capacity, financial capacity, Manpower and machineries capacity, Technology capability and Management efficiency. Quality Assurance is conducted in 4 stages of production.

Competitive price

Our vast networking in Bangladesh allows us to provide the cheapest price available in Bangladesh. Receiving and verifying the quotations of suppliers by studying their suitability both in terms of quality and capacity to meet contractual requirements. Negotiation and finalization of price.

Sample development

Our sampling team can make development sample within 7-10 days With Collecting customer’s requirement of fabric and style. Identifying and selection of appropriate source. Preliminary screening by inspection and testing. Forwarding samples to the customers and receiving feedback.

Shipment: Arrange vessel for shipment with the forwarders and follow up shipment points for smoother connections. The above are some of the important activities we perform to provide a very effective service.